|

|

| Research |

|

Virtual Prototyping

Pneumatic Muscle Actuators Shape Memory Alloys (SMA) Actuators Bioengineering Finite Element Model Updating Structural Modifications Robotics |

| Robotics |

||||||

|

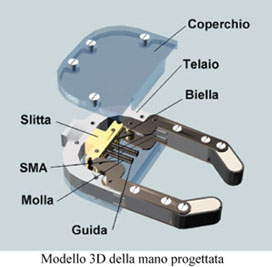

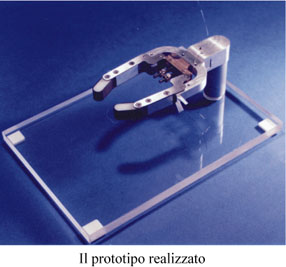

Small Gripper with Shape Memory Alloy Actuators (SMA)

SCARA Robot with flexible structure Parallel Robot driven by pneumatic actuators Parallel Robot with Shape Memory Alloy Actuators Parallel robot with SMA actuators with internal sensor effect Small Gripper with Shape Memory Alloy Actuators (SMA)

The constructive solution for the realization of the mechanism consists

in a structure to which the mobile elements are bound. The actuators in

SMA are in number of 4 in a symmetrical disposition to avoid couples of

rotation that would increase the friction strengths between sleigh and

guide. For the block of the SMA actuators on the structure and on the

sleigh, adjustable special systems of fixing have been developed. The

fingers have the particularity to be adjustable in operation of the

dimension of the object to grab. The springs are stopped on the guides

through two adjustable locks to allow regulations for the correct operation.

The hand has been realized in light material, Aluminium and Nylon, to

limit the weights. Last phalanx are dressed in rubber to improve the

conditions of gripping. The dimensions are 19 mm x 60 mm x 80 mm. The

command for grip it happens with the passage of current through the

actuators that develop the necessary thermal power to the deformation

for Joule effect. Experimental verifications of the abilities of grip

have been effected. It has been commanded gripping of objects with

parallel faces and cylindrical objects with different dimensions and

weights.

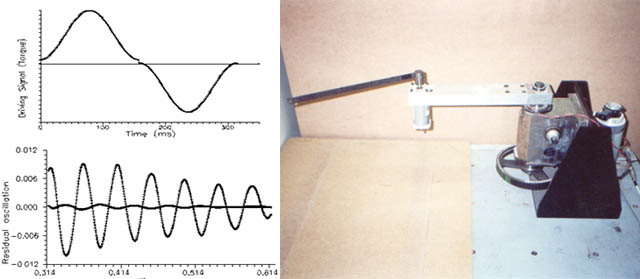

SCARA Robot with flexible structure

The objective is the improvement of the performances of the arms of robot

looking for very small times of positioning. In these cases classical

control goes to crisis for the impossibility to check the structural

vibrations. It is possible to adopt innovative strategies of control

that think about the vibration behaviour of the structure and that they

allow fast positioning without the onset of vibrations. An opportune

law kinematics is been individualized by to apply to the flexible link

which is able to effect brief positioning (time = 2 fundamental period

of the structure) with notable reduction of oscillations positioning.

In the first figure the torque law is showed and in the second figure

the comparison about the end oscillations positioning between a

classical law of control and with the proposed method. It notice a

reduction about 20 times of the peak-peak of the oscillation.

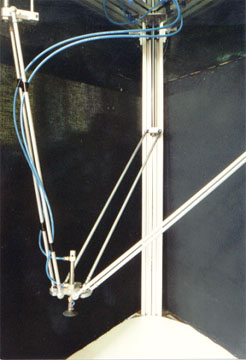

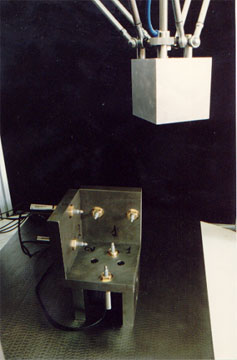

Parallel Robot driven by pneumatic actuators

The robot has an architecture parallel kinematics and it’s operated

with traditional pneumatic actuators. The control system is based on

logical Fuzzy. It's a machine with 3 degrees of freedom (DOF) with

dimensions around 2m x 0.8m x 1m. The working volume has form "lenticolar."

A static characterization of the robot has been effected. It has been

possible to characterize the precision of positioning and the repeatability

of the robot. A specific measurement equipment has been set-up. It consist

of high precision cube mounted on the moving plate of the robot, and fixed

trihedral gauge with six LVDT trasducers.

They result: Precision of positioning: 2mm Repeatability of positioning: 5.6 mm It has been made a model for the forecast of the dynamic behaviour of the robot. The model has been verified experimentally through measures of the frequencies proper of the structure in the different points inside the working volume. The model experimentally validate has been used for developing mapping, on the working volume, of the frequencies proper of the robot.

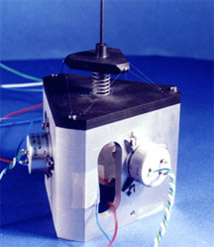

Parallel Robot with Shape Memory Alloy Actuators

The objective of this study is the realization of a small manipulator

to 3 DOF with kinematics parallel structure usable as device of

orientation or for the manipulation of small objects. The robot has

size of 180mm x 100mm x 100mm and a working volume of lenticular shape

of the height of 2 mm and diameter of 24 mm. For the movements it has

been used wires in Shape memory alloy (SMA) in Ni-Ti of the diameter

of 150 micron. The structure kinematics is parallel and the wires are

maintained in tension through a mechanical spring between the base

plate and the moving plate. It has set a control system in closed

loop. The thermal power is produced for Joule effect making to cross

from current the actuators themselves. The control law is a simple

proportional one and it uses a feedback signals of a position’s

sensor of resistance. The kinematics architecture foresees the actuators

connected to the base plate through cylindrical hinges to 120° and

the moving plate with spherical hinges. This solution has realized

with the actuators in isosceles triangle disposition. This configuration

besides furnishing a simple constructive solution to the functional

specifications, allows also an amplification of the movement of the

actuators. On the base of the project the prototype of the robot has

been realized. Some preliminary verifications of the movements of

the single axis and pursuit of trajectories have been effected that

require the control coordinated of everybody three axis.

Video of the robot (8Mb)

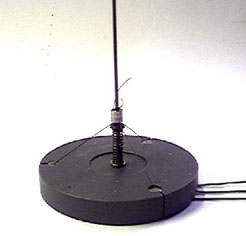

Parallel robot with SMA actuators with internal sensor effect

The objective has been the realization of a manipulator, of small

dimensions, to three degrees of freedom. For the driving it has been

used wires in SMA and the feedback control system it uses the internal

sensor effect of the material. In this way it has been possible to

realize a structure with small dimensions. They have been effectuated

movements of the single axis and movements coordinated that they

contemporarily involve all the axis. In the figure is showed the

realized prototype.

|