|

|

| Ricerca |

|

Virtual Prototyping

Pneumatic Muscle Actuators Shape Memory Alloys (SMA) Actuators Bioengineering Finite Element Model Updating Structural Modifications Robotics |

| Shape Memory Alloys (SMA) Actuators |

||||

|

INTRODUCTION

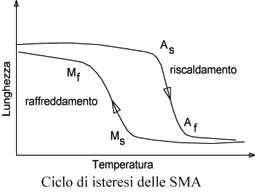

The shape memory alloys (generally leagues Ni-TI) introduces the ability,

unusual for other types of materials, "to remember" his own original shape.

This mechanical behaviour is correlated to a transformation of the

crystal lattice that is verified inside the league. Such transformation

converts the stable crystal lattice to high temperature (austenitic phase)

in one stable to low temperature (martensitic phase). At low temperature

these materials are easily deformable while heating them it has the

transformation of the martensite in austenite and in this phase the

material develops notable strengths recovering its original form.

The transformation is accompanied by hysterisis. These materials are

available in varied forms as ribbons, foils, wires and helicoids. For

the wires the obtainable reversing deformations are of 5% - 8% and

the maximum tensions developable arrive to around 200 MPa. To supply

thermal energy is possible to use the effect Joule through crossing

of current.

The shape memory alloys (generally leagues Ni-TI) introduces the ability,

unusual for other types of materials, "to remember" his own original shape.

This mechanical behaviour is correlated to a transformation of the

crystal lattice that is verified inside the league. Such transformation

converts the stable crystal lattice to high temperature (austenitic phase)

in one stable to low temperature (martensitic phase). At low temperature

these materials are easily deformable while heating them it has the

transformation of the martensite in austenite and in this phase the

material develops notable strengths recovering its original form.

The transformation is accompanied by hysterisis. These materials are

available in varied forms as ribbons, foils, wires and helicoids. For

the wires the obtainable reversing deformations are of 5% - 8% and

the maximum tensions developable arrive to around 200 MPa. To supply

thermal energy is possible to use the effect Joule through crossing

of current.

ACTUATOR WITH DEDICATED SENSOR It’s developed an actuator with Shape Memory Alloy thread-like. The actuator effects the continuous positioning through a control system in closed loop.  The thermal power is produced for effect Joule making to cross from

current the actuators. The control system is type proportional and

it uses a retroaction’s signal of a resistance sensor position.

It's realized a controller software that he pilots a data acquisition

card. In exit is used a counter/timer able to furnish a signal

type train of impulses with modulation of ampleness (PWM). In entry,

for measure the position, a digital analogical converter to 16 bit

is used. To furnish the power has been realized a circuit with

fotoaccoppiatore, that it enable the power flow from a power

supplier to the actuator, piloted to low power by the counter/timer.

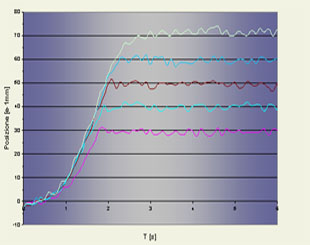

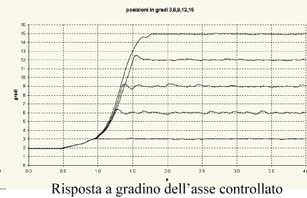

The figure shows the step response of an checked axle for different

values of the reference.

The thermal power is produced for effect Joule making to cross from

current the actuators. The control system is type proportional and

it uses a retroaction’s signal of a resistance sensor position.

It's realized a controller software that he pilots a data acquisition

card. In exit is used a counter/timer able to furnish a signal

type train of impulses with modulation of ampleness (PWM). In entry,

for measure the position, a digital analogical converter to 16 bit

is used. To furnish the power has been realized a circuit with

fotoaccoppiatore, that it enable the power flow from a power

supplier to the actuator, piloted to low power by the counter/timer.

The figure shows the step response of an checked axle for different

values of the reference.

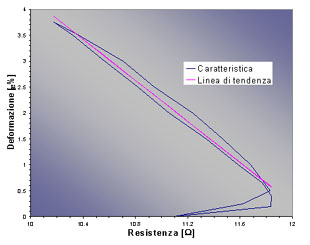

ACTUATOR WITH EFFECT INTRINSIC SENSOR An actuator with Shape Memory Alloy thread-like for the continuous positioning through a control system in closed-loop without external sensor for measure the position it is developed. In this case has been used effect intrinsic sensor of the material that, for the SMA-wires, it consists in a linear response between electric resistance of the wire and length of wire. This characteristic allows to know the length of the actuator through an measure of electric resistance. The thermal power is produced for effect Joule and the control it’s proportional. The controller pilots a data acquisition card. In exit it’s used a counter/timer able to furnish a modulation signal of ampleness (PWM). In entry, for the measure of the electric resistance of the SMA-wire is used a digital analogical converter to 16 bit.

|